Prinston Pharmaceutical is dedicated to optimizing quality and reducing cost.

Prinston Pharmaceutical takes full ownership of the manufacturing process by operating its own state-of-the-art API and formulation manufacturing facilities. This not only allows Prinston Pharmaceutical to stay responsive to client demands and global circumstances but also reduces overall manufacturing costs by minimizing outsourcing overhead. These savings are then reinvested into its own manufacturing technologies to continue innovating and setting industry standards.

As a global leader in generic pharmaceutical manufacturing, Prinston Pharmaceutical leverages the support of its parent company, Zhejiang Huahai, to produce pharmaceuticals both domestically and internationally. This support enables Prinston Pharmaceutical to respond to worldwide client demands.

A Reliable Global Supply

Prinston Pharmaceutical leverages an international supply chain to produce high-quality pharmaceuticals at scale. To manufacture APIs, Prinston Pharmaceutical utilizes facilities in Xunqiao, China, and Nantong, China. Not only are these facilities experienced with conventional technolgies for chemically synthesized APIs, Prinston Pharmaceutical's API manufacturing facilities are capable of green synthesis, crystallization process, impurity control and enzymatic catalysis. Through such processes, Prinston Pharmaceutical has an annual production capacity at more than 3000 tons.

In addition to Prinston Labs, Prinston Pharmaceutical operates a formulation manufacturing facility in Zhejiang, China. To enhance efficiency, these facilities are equipped with a complete set of automatic pharmaceutical manufacturing and packaging equipment. Combined with its North Carolina facility, these locations have an annual capacity of 30 billion units for regular oral solid products, 500 million units for high-potency oncological oral solids, and 20 million units of liquid and powder injections.

Prinston Pharmaceutical's manufacturing facilities comply with the highest global standards. All production facilities adhere to international cGMP standards and have been certified and inspected by regulatory agencies such as:

- China NMPA

- FDA

- BGV

- EMA

- PMDA

- WHO

- TGA

- COFEPRIS

- TMMDA

American Manufacturing

Prinston Pharmaceutical utilizes its American subsidiary, Prinston Laboratories, to manufacture its generic pharmaceuticals. Prinston Laboratories is a manufacturing site in Charlotte, North Carolina that has 170,975 ft² of facility space dedicated to producing its 5 billion oral solid doses within the United States.

To accomplish its mission of producing high quality oral solid doses, Prinston Laboratories uses a proccess comprised of: dispensation, granulation, blending, compression, encapsulation, coating and packaging.

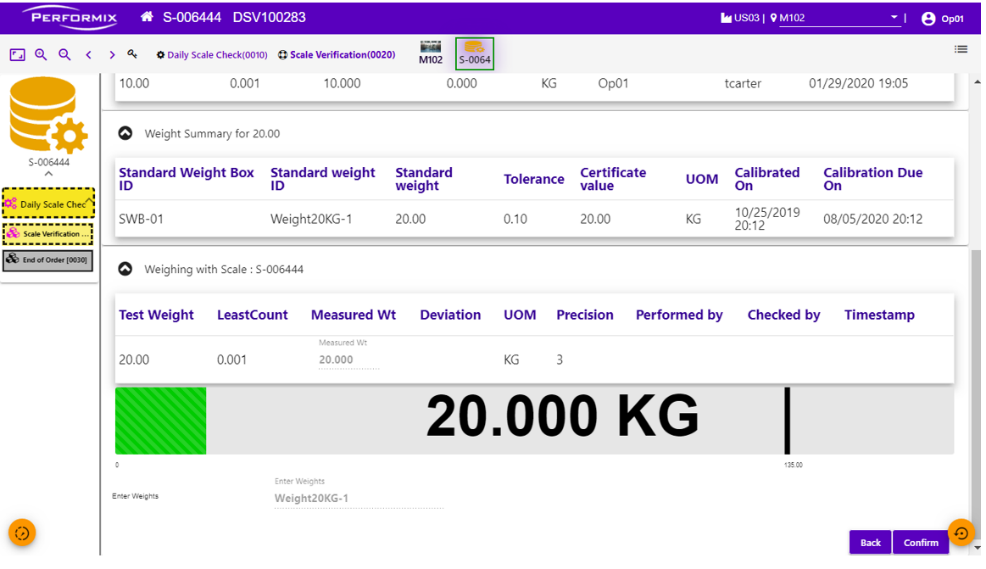

We have four dispensing suits. We also use electronic batch records to increase accuracy, error reduction and inventory control.

Our facilities are capable of both dry and wet granulation. For top spray granulation, we use Freund-Vector equipment with the following capacities: 240 kg to 480 kg, 314 kg to 628 kg, and 62 kg to 120 kg. Additionally, for roller compactor dry granulation, we use Alexanderwerk equipment that is capable of up to 50 kg per hour. Finally, our wet granulation uses Lodige-Littleford equipment with a capacity of 100 kg to 200 kg.

Our facilities have several blender machines with varying capacities. Our largest blenders are our two double cone 150 ft³ blenders, capable of vacuum transfer at 800 kg to 1250 kg. Our other double cone blenders include a 60 ft³ blender with a capacity of 400 kg to 600 kg, a 30 ft³ blender with a capacity of 250 kg to 400 kg, and a 10 ft³ blender with a capacity of 50 kg to 100 kg. We also have a 3 ft³ V blender with a capacity of 10 kg to 70 kg. Our smallest blender is a 1.3 ft³ blender with a capacity of 10 kg to 20 kg.

Our facilities have several compression machines with varying capacities. Our two largest Korsch machines are capable of producing 418,000 tablets per hour, and our other bi-layer capable Korsch machine can produce 90,000 tablets per hour. Our larger Kikusui machine is capable of producing 86,000 tablets per hour, and our six other Kikusui machines can produce a combined total of 320,000 tablets per hour.

Our facilities have Accela-Cota and O'Hara Lab coating equipment. The two 60" Accela-Cota units each at 350 kg capacity uses perforated pans and are able to perform enteric and film coating. Our 48" Acceela-Cota eqipment at 125 kg capacity also uses a perforated pan and is also capable of an enteric and film coating. Our O' Hara Lab machine uses interchangeable pans at 18", 24" and 36".

Our facilities uses a Bosch machine capable of 150,000 capsules per hours. It is capable of a bead or powder fill, has a 100% check weigh system and a statistical process weight control.

Our packaging process utilizes equipment from Lakso Slat and Cremer. Our three Lakso Slat machines are each capable of 10 to 80 bottles per minute, and our Cremer machine is capable of 10 to 60 bottles per minute.